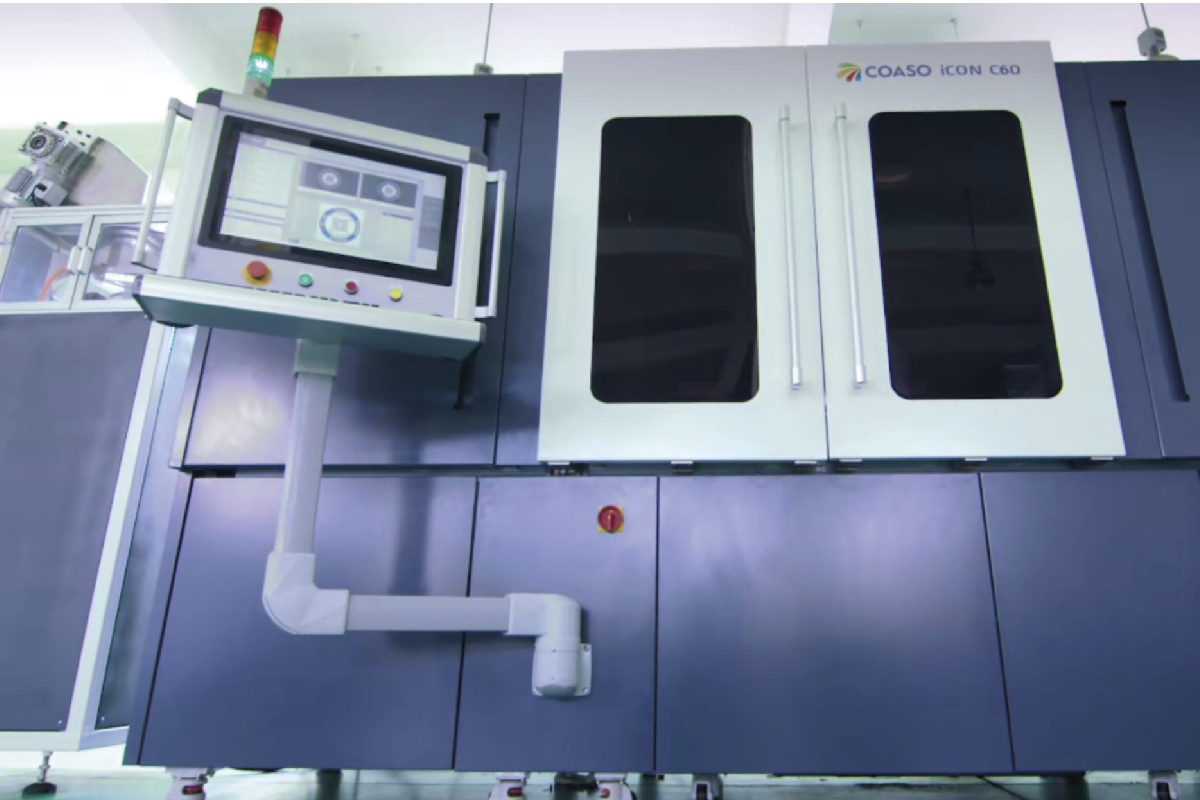

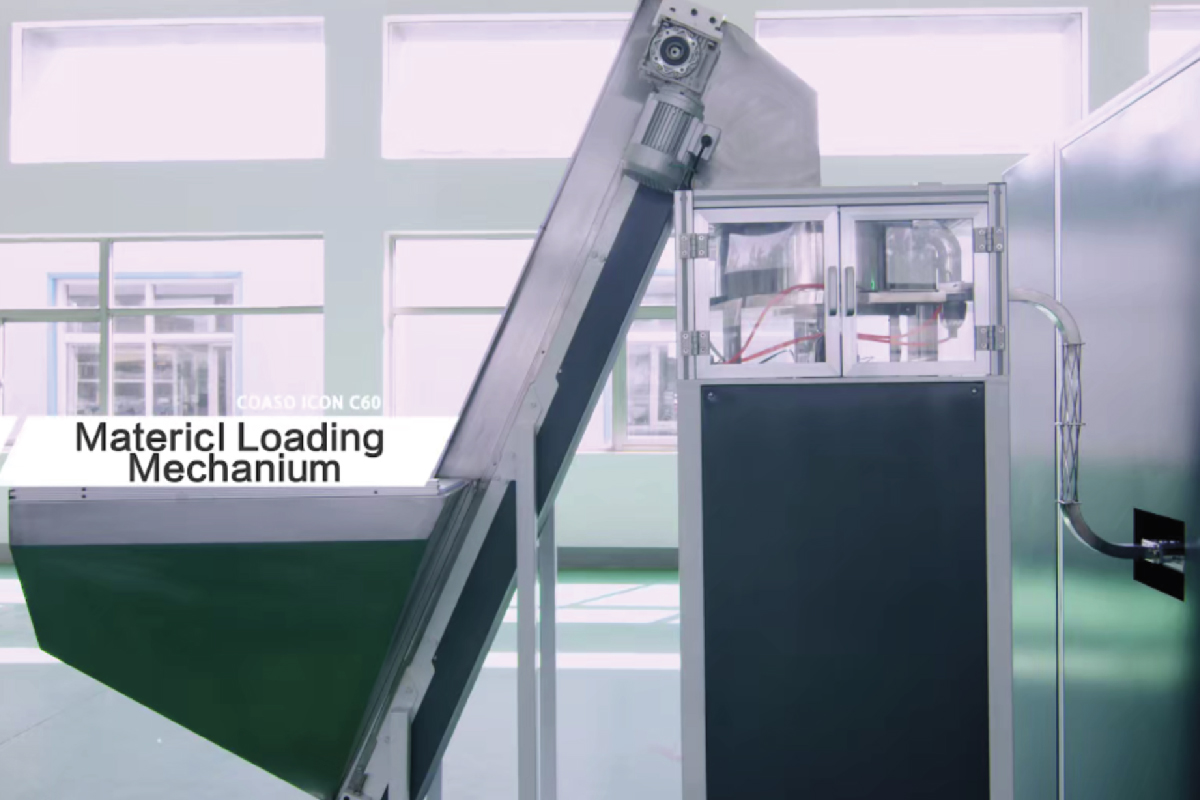

iCON C60 Series Colour Bottle Caps Digital Press

With innovative design concepts and avariety of functional configurations, the iCON C60 digital press makes color printed bottle caps with strong visual effects and security features to enhance high value-added products. It can be widely used in various caps printing of drinks, alcohols, foods, medicines, daily chemical products, and so on. Which enhances the users core competitiveness of their products, to bring a more competitive advantage and business opportunities, according to the user's production needs, it provides personalized and customized services to help with the customers in-depth development of the potential market in the packaging industry.

Main Features

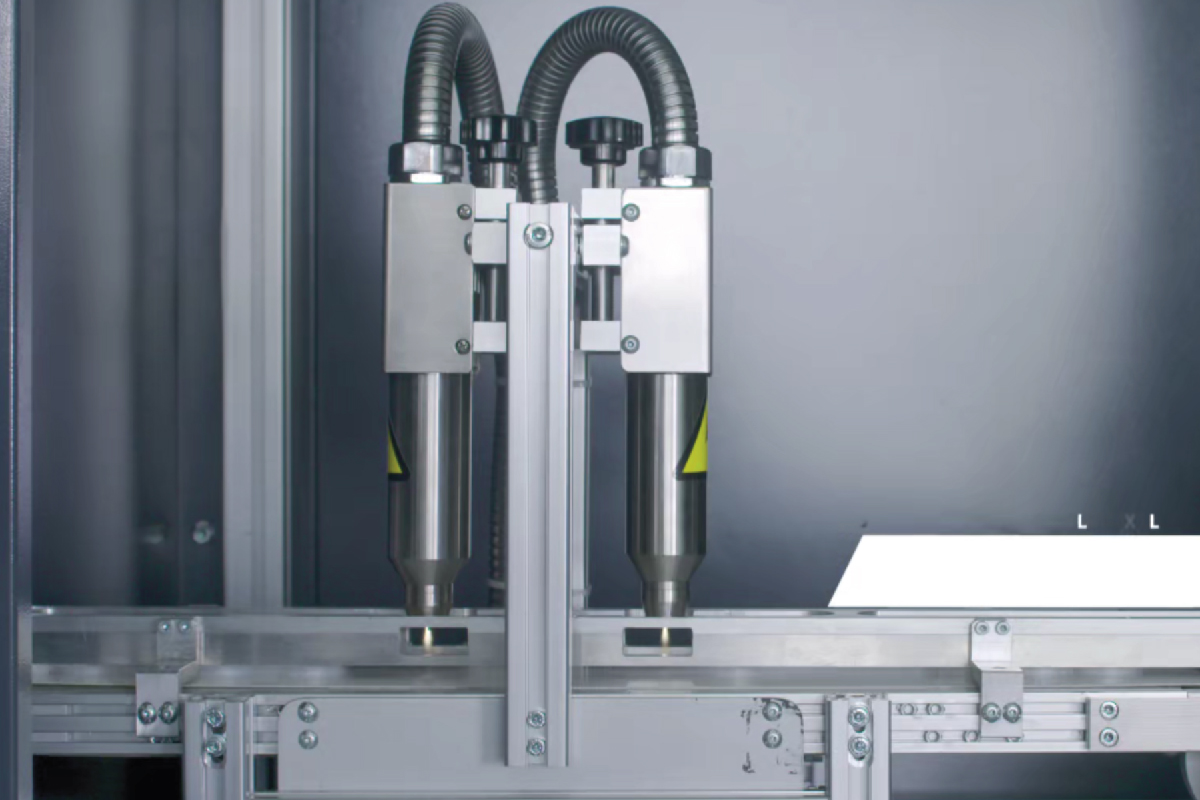

Direct inkjet printing of UV curing on plane. Flexible print on bottle caps.

High-effect LED curing technology. The whole system uses long-life and environmental LED, without drying at post-press.

Industrial circular ink supply. circular ink supply with the bottle of1.5L

Printing unit modularizing: configurate the quantity of printing unit as required.

High speed printing: the printing speed can reach to 50000 pieces / hour

Printing quality inspection online: inspect printing quality of products and internal code (optional) online through visual technology, and eliminate defective products automatically

Environmental color printing on actual objects. All images are printed on actual objects which is low cost, safe and high efficient.

High definition color image printing. the machine can print color images on bottle caps of various materials, the resolution can reach up to 360dpi

The invisible anti-fake technology. Users can select customized invisible ink.

Variable data printing. The printing image can be adjusted at real time according to setting data.

Print two QR codes at a time. The machine can print the internal and external QRcodes (identifying codes) on lucid bottle cap at a time.

Interlock verification between internal and external codes. The core competence of products is promoted through interlock verification between internal and external codes, which brings more competitive advantage and business opportunity for users.

Application

iCON C60 can be used in various bottle caps printing of drinks, alcohol, foods, medicines, daily use chemicals, etc.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|